3D Origami Structures

Feasibility

study on different fabrication methods for small-scale origami meta-materials.

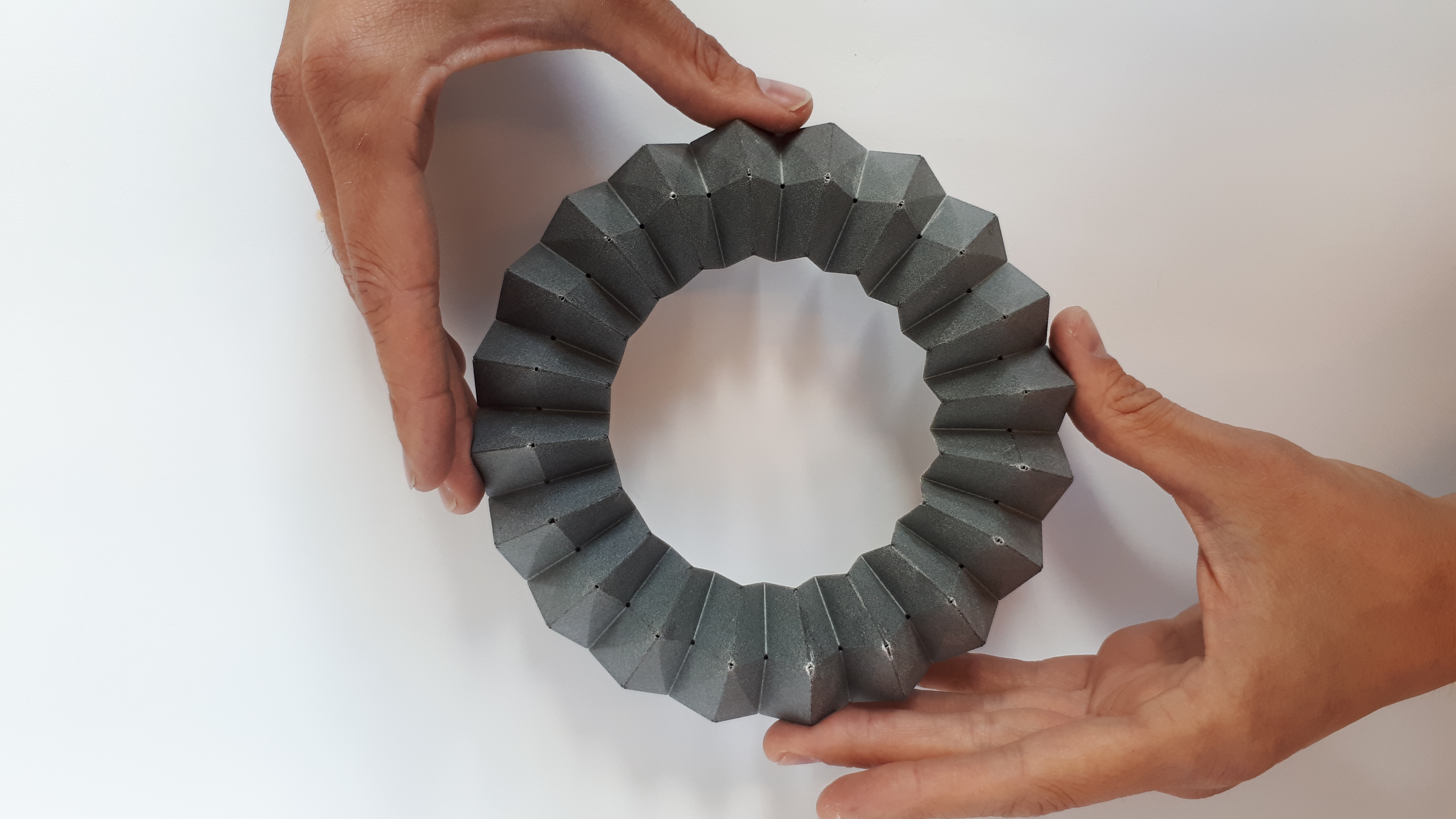

Most prominent design was a donut-shaped ring that should remain circular when

being compressed.

The most challenging aspect of making origami structures, is the stiffness-difference between facets and creases. Multiple different forms of 3D printing where investigated. Selective laser sintering methods allow for very thin creases that act as living hinges. Printing right up to the limit of this method yields relatively good results, although the stiffness of the joints influences the movement.

Another option is to use a multi-material printer. The creases can now be printed in a different material with a lower stiffness than the facets. In this case, the creases are printed in a synthethic rubber. This yields a smooth motion, but the rubber adds some unwanted hysteresis to the system.

Additionally, a small segment of origami was also manufactured using injection moulding.